The Fundamentals of Gravity Sewer Systems

We all rely on unseen infrastructure every day. Beneath our communities, vast networks of pipes quietly carry wastewater away. These are often gravity sewer systems, a fundamental part of public health and environmental protection.

We all rely on unseen infrastructure every day. Beneath our communities, vast networks of pipes quietly carry wastewater away. These are often gravity sewer systems, a fundamental part of public health and environmental protection.

These systems use a simple, yet powerful, principle: gravity. Wastewater flows downhill through a series of pipes to treatment facilities. While this sounds straightforward, ensuring these complex systems operate smoothly and reliably requires careful engineering and the right equipment.

In this guide, we will explore how gravity sewer systems function. We’ll look at the challenges they face and how specialized valves are essential for their integrity and efficiency. Understanding these components is key to maintaining healthy and resilient infrastructure for our communities.

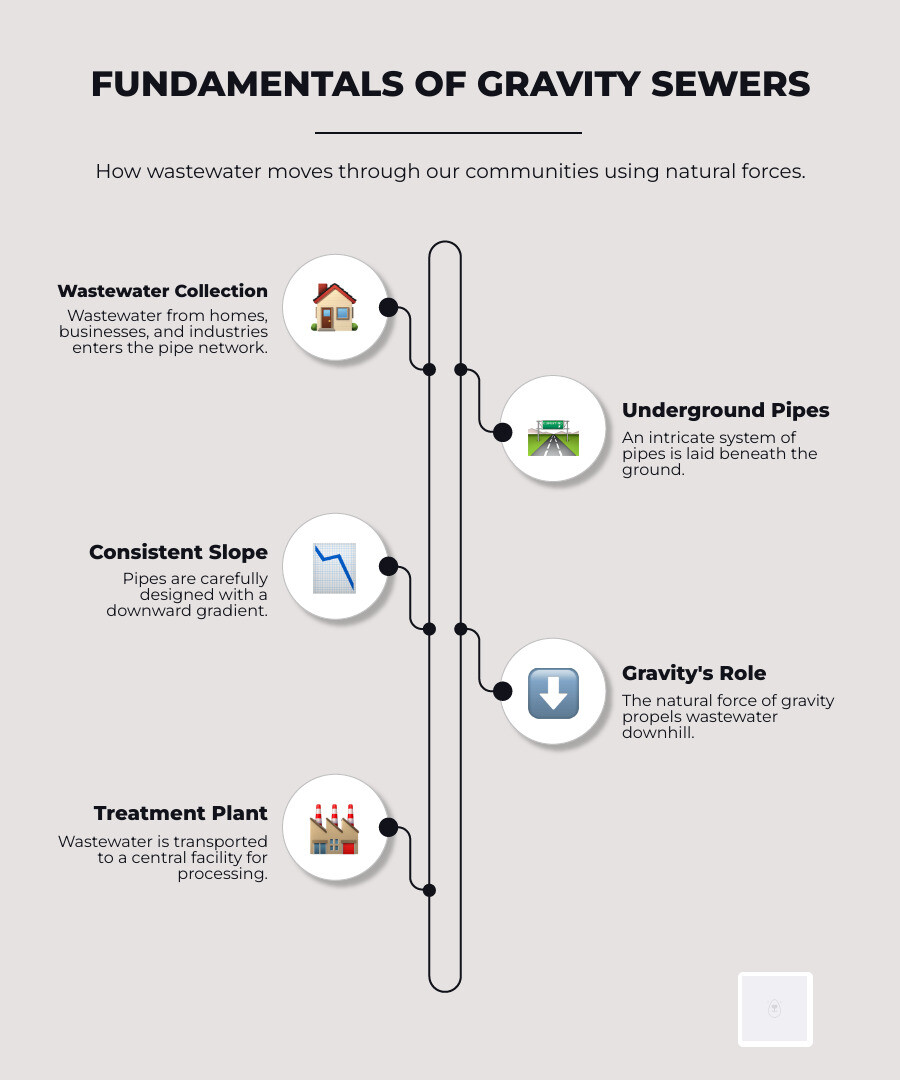

How Gravity Moves Wastewater

A gravity sewer system is an intricate network of underground pipes designed to transport wastewater from homes, businesses, and industries to a treatment plant. Its fundamental principle is neatly simple: using the natural force of gravity. Wastewater flows downhill through a carefully laid system of pipes, eliminating the need for constant pumping.

Within a gravity sewer system, wastewater typically travels through three main types of sewer lines:

- Lateral Lines: These are the smallest pipes, connecting individual properties to the larger main lines.

- Branch Lines: These collect wastewater from several lateral lines and direct it towards the main sewer lines.

- Main Lines (or Trunk Sewers): These are the largest pipes in the system, collecting wastewater from multiple branch lines and carrying it to a central collection point or directly to a wastewater treatment facility.

The wastewater itself is primarily composed of what we categorize as black water and grey water. Black water originates from toilets and kitchen sinks, containing fecal matter, grease, and high levels of pathogens. Grey water, on the other hand, comes from sources like washing machines, showers, and bathroom sinks, generally having a lower level of contamination. Managing both effectively is crucial for public health.

To facilitate inspection and maintenance, gravity sewer systems incorporate utility maintenance holes, commonly known as manholes. These vertical shafts provide access to the underground pipes, allowing workers to monitor flow, clear blockages, and perform necessary repairs without extensive excavation.

Key Operational Factors

The efficient operation of a gravity sewer system hinges on several critical engineering factors that ensure continuous flow and prevent blockages.

One of the most vital is self-cleansing velocity. This refers to the minimum flow speed required to prevent solid particles in the wastewater from settling at the bottom of the pipe. If the velocity is too low, solids accumulate, leading to blockages, reduced capacity, and potential system failures. Conversely, a sufficient velocity ensures that suspended particles are carried along and that any already-deposited particles are scoured away, keeping the pipes clean. Engineers typically aim for a self-cleansing velocity of 0.6 to 0.9 meters per second during peak dry weather conditions. This velocity is essential not only for preventing settlement but also for scour, which is the natural cleaning action that removes accumulated debris.

Achieving this self-cleansing velocity relies heavily on a consistent downhill gradient. The pipes must be laid with a continuous slope, allowing gravity to propel the wastewater forward. The steeper the gradient, the faster the flow. However, maintaining a consistent downhill gradient across varying terrains can be challenging, often requiring deep excavation, which adds to construction costs and complexity. In situations where deep excavation is problematic due to factors like poor soil conditions or high water tables, alternative solutions such as small diameter gravity sewer systems (SDGSs) might be considered, as they offer more flexibility in slope gradient.

The pipe material and diameter are equally crucial. Common pipe materials include concrete, PVC, ductile iron, and cast iron, each chosen for its durability, corrosion resistance, and cost-effectiveness. The diameter of the pipes must be carefully calculated to accommodate anticipated flow volumes while maintaining the self-cleansing velocity. Gravity sewer pipes are usually 6 inches, 8 inches, or larger in diameter to prevent suspended solids from settling. Larger diameters can handle more flow but require a precise gradient to prevent sluggish movement.

Another factor influencing gravity sewer performance is the proper functioning of connected septic tanks. While not part of the municipal gravity sewer itself, a malfunctioning septic tank can allow an excessive amount of suspended solids and corrosive gases (like hydrogen sulfide) into the system, contributing to blockages and pipe deterioration.

Why Engineered Gravity Sewer Valves are Critical for System Integrity

Even with careful design, gravity sewer systems face inherent challenges that can compromise their integrity and efficiency. These challenges often stem from the dynamic nature of wastewater flow, the presence of air, and external factors like heavy rainfall. This is where the role of specialized, engineered valves becomes absolutely critical. Our commitment to robust infrastructure solutions drives us to emphasize the importance of high-quality components, including International Valve engineered gravity sewer valves.

The Dangers of Trapped Air and Vacuum

One of the most insidious threats to pipeline integrity in any fluid conveyance system, including gravity sewers, is the presence of trapped air and the potential for vacuum conditions.

Trapped air can accumulate at high points in the pipeline, forming air pockets. These pockets act as obstructions, reducing the effective cross-sectional area of the pipe and thereby decreasing flow capacity. This phenomenon, known as air lock, can significantly impede the flow of wastewater, leading to sluggish movement, increased retention times, and potential overflows. In extreme cases, large air pockets can even contribute to pressure surges when they are rapidly compressed by incoming fluid, causing a “water hammer” effect that can damage pipes and fittings. For systems relying on pumps, trapped air can lead to cavitation, causing premature wear and failure of pump components.

Even more dangerous is the formation of a vacuum. When flow rates suddenly decrease or a pipe rapidly drains (e.g., due to a downstream break or intentional shutdown), negative pressure can develop within the pipeline. If not properly managed, this negative pressure can create a vacuum strong enough to cause pipeline collapse. This structural failure can lead to costly repairs, environmental contamination, and significant service disruptions. The presence of vacuum can also lead to column separation, where the wastewater column breaks apart, creating voids that then violently rejoin, generating severe pressure surges.

Mitigating Pressure Surges and Backflow

Beyond air and vacuum, gravity sewer systems must contend with other dynamic forces, particularly pressure surges and the risk of backflow.

Pressure surges, often referred to as water hammer, occur when there is a sudden change in flow velocity. This can happen due to rapid valve closures, pump starts or stops, or the sudden collapse of a vacuum void. These surges create transient high-pressure waves that travel through the pipeline, potentially exceeding the pipe’s design pressure and causing bursts, joint failures, or damage to connected equipment. While gravity sewers are generally low-pressure systems, surges can still occur, especially during heavy rainfall events that rapidly increase flow or when a blockage suddenly clears.

Backflow is another critical concern, particularly in areas prone to heavy rainfall or where homes have fixtures below street level. When municipal sewer lines become overwhelmed (e.g., during a storm), the wastewater level can rise, causing it to flow backward into connected properties. This can lead to devastating sewage backups, causing extensive property damage, health hazards from contamination, and significant cleanup costs.

To prevent these issues, specialized valves are employed. These valves are engineered to:

- Release trapped air proactively.

- Allow air to enter the pipe rapidly to prevent vacuum formation and pipeline collapse.

- Mitigate pressure surges by cushioning rapid flow changes.

- Prevent backflow, ensuring wastewater only moves in one direction.

By effectively managing these dynamic forces, engineered valves protect the physical infrastructure, ensure the continuous and efficient transport of wastewater, and safeguard public health and property.

A Guide to Different Types of Gravity Sewer Valves

The selection of appropriate valves is paramount for the long-term efficiency, reliability, and safety of gravity sewer systems. These specialized components perform distinct functions, from managing air and preventing vacuum to controlling flow direction and protecting against backflow. Our comprehensive range of sewer valves is designed to address the unique demands of wastewater infrastructure.

Air Release and Vacuum Break Valves

Air release and vacuum break valves are indispensable for maintaining the hydraulic efficiency and structural integrity of gravity sewer pipelines. These valves serve a dual function:

- Air Release: They automatically vent accumulated air from the pipeline during normal operation. As wastewater flows, air can become entrained or separate from the liquid, forming pockets at high points. If not released, these air pockets can restrict flow, create air locks, and contribute to pressure fluctuations.

- Vacuum Break (or Air Admission): Equally important, these valves rapidly admit large volumes of atmospheric air into the pipeline when internal pressure drops below atmospheric pressure, preventing vacuum formation. This is crucial during rapid draining events, pump shutdowns, or pipe breaks, which could otherwise lead to pipeline collapse or column separation.

For gravity sewer systems, which often operate at low or even zero pressure, the ability of these valves to function effectively under such conditions is critical. For instance, the Vent-Tech Model SWG sewer valve is engineered for systems where the hydraulic grade line (HGL) is consistently maintained above 3 psi, requiring a minimum of 3 psi for sealing. However, many gravity sewer applications do not maintain this consistent pressure. For these challenging scenarios, the Vent-Tech Model SZG sewer valve seals reliably at zero psi minimum, making it an ideal solution for low-pressure and zero-pressure sewer systems where traditional valves might fail.

Check Valves and Backflow Prevention

Check valves are essential components in gravity sewer systems, primarily designed to ensure one-way flow and prevent backflow. This function is vital for protecting both the infrastructure and connected properties from contamination and damage.

A common type of check valve used for this purpose is the backwater valve. A backwater valve allows water or sewage to flow only one way – away from your house. When the municipal sewer system becomes overloaded, such as during heavy rainfall, the backwater valve automatically closes, preventing sewage from backing up into basements or other low-lying areas of a property. Inside the valve, a flap remains open during normal flow. If reverse flow occurs, floaters within the valve lift the flap, sealing the pipe. Once the threat of backflow subsides, the flap reopens, restoring normal flow.

Other forms of check valves, such as flap gates and swing checks, are also used in various parts of the sewer network, particularly at outfalls or junctions. Flap gates, for example, are often installed at the end of pipes to allow outflow while preventing tidal ingress, debris, or small animals from entering the system. These valves are crucial for protecting downstream treatment facilities from unexpected surges and preventing upstream contamination.

Specialized Engineered Gravity Sewer Valves for Modern Infrastructure

Beyond the foundational air/vacuum and check valves, modern gravity sewer systems benefit from highly specialized engineered gravity sewer valves designed to tackle specific, complex challenges. These innovations improve system performance, reduce maintenance, and extend infrastructure lifespan.

One significant area of specialization is zero-pressure sealing. As discussed, many gravity sewer lines operate with very little or no internal pressure. Traditional valves often rely on a minimum pressure differential to achieve a proper seal. However, specialized valves, like certain models of Vent-Tech sewer valves, are engineered to seal reliably even at zero hydraulic head. This ensures complete protection against vacuum and effective air release in the most challenging low-pressure environments.

Another critical consideration is handling high-grease environments. Wastewater often contains fats, oils, and grease (FOG) which can accumulate and foul valve mechanisms, leading to malfunctions and increased maintenance. Engineered valves designed for these conditions incorporate features like self-flushing designs and robust materials that resist FOG buildup, ensuring continuous operation and reducing the frequency of costly cleanings.

Compact designs are also increasingly important. As urban spaces become denser and infrastructure corridors more constrained, the physical footprint of components matters. Specialized valves are now available in more compact forms, allowing for installation in limited spaces, such as within existing manholes or in areas with restricted vertical clearance. The Vent-Tech Model SKW, for example, is specifically designed for severely height-restricted installations.

Furthermore, these specialized valves emphasize corrosion resistance. Given the corrosive nature of wastewater, particularly with the presence of hydrogen sulfide gas, valves must be constructed from materials that can withstand harsh chemical environments. Stainless steel and high-grade ductile iron with advanced coatings are commonly used to ensure long-term durability and minimize the need for frequent replacement.

For a deeper dive into selecting the optimal valve for your specific project needs, we encourage you to explore our comprehensive Sewer Valves product lines or use our Help Me Choose a Sewer Valve resource.

Key Factors in Choosing the Right Valve for Your System

Selecting the appropriate gravity sewer valves is a decision that impacts the entire system’s performance, longevity, and maintenance burden. It requires a thorough understanding of both the system’s operational demands and the specific characteristics of the wastewater being conveyed.

Assessing System Conditions

Before choosing a valve, a detailed assessment of the system’s conditions is essential. Key factors to consider include:

- System Pressure: While gravity sewers are generally low-pressure, understanding the range of pressures (including potential for zero pressure or transient surges) is crucial. Some valves require a minimum operating pressure to seal effectively, while others, like the Vent-Tech Model SZG, are designed for zero-pressure sealing.

- Flow Characteristics: Evaluate the typical and peak flow rates. The valve must be sized correctly to accommodate these flows without causing excessive head loss or creating turbulence that could lead to air entrainment.

- Wastewater Composition: The nature of the wastewater is a primary determinant for material selection. Is it primarily domestic sewage, or does it contain industrial discharges? The presence of corrosive chemicals, high levels of suspended solids, or significant amounts of fats, oils, and grease (FOG) will dictate the required material resistance and design features (e.g., self-flushing capabilities).

- Debris: Sewer systems often carry various forms of debris, from rags and wipes to grit and organic matter. Valves must be designed to either pass this debris without snagging or to be easily accessible for cleaning.

- Environmental Factors: Consider the installation environment. Is the valve exposed to extreme temperatures, corrosive soil, or potential for physical damage?

Material and Design Considerations for Engineered Gravity Sewer Valves

Once system conditions are understood, the choice of valve material and design becomes critical for ensuring long-term performance and minimal maintenance.

Common valve materials include:

- Ductile Iron: Offers high strength and durability, often used for valve bodies and components. It can be coated with fusion-bonded epoxy for improved corrosion resistance.

- Stainless Steel: Provides superior corrosion resistance, especially in harsh chemical environments or where hydrogen sulfide gas is present. Various grades (e.g., 304SS, 316SS) are chosen based on the specific corrosive agents.

- PVC (Polyvinyl Chloride): Lightweight and corrosion-resistant, often used for smaller diameter valves or backwater valves in residential applications.

Corrosion resistance is paramount. Wastewater is inherently corrosive, and valves must be able to withstand chemical attack over decades of service. This involves not only the body material but also internal components, seals, and fasteners.

Durability is another key factor. Valves in gravity sewers are subjected to continuous flow, potential abrasive solids, and dynamic pressure changes. Robust construction ensures they can endure these conditions without premature wear or failure.

Maintenance access and service life are also vital design considerations. Valves should be designed for ease of inspection, cleaning, and repair. Features like removable access covers, clear visual indicators, and self-flushing mechanisms can significantly reduce maintenance burdens and extend the operational life of the valve. The goal is to select valves that offer a long, trouble-free service life, minimizing disruptions and operational costs.

Frequently Asked Questions about Gravity Sewer Valves

Why is managing air in a sewer pipe so important?

Trapped air can create pockets that block or slow down flow, reduce the pipe’s capacity, and cause pressure surges that can damage pipes and equipment. Properly functioning valves release this air to ensure the system runs efficiently and safely. Air pockets can also lead to column separation, where the water column breaks apart, and then violently rejoins, causing severe water hammer. Effective air management prevents pipeline collapse due to vacuum and protects the entire infrastructure from mechanical stress.

What is the difference between a gravity sewer and a force main?

A gravity sewer uses the natural force of gravity, relying on a consistent downward slope to move wastewater. It is typically a non-pressurized system, often requiring deep excavation to maintain the necessary gradient. Force mains, on the other hand, are pressurized pipelines that use pumps to move wastewater. They are employed when gravity flow is not feasible, such as when wastewater needs to be transported uphill, across flat terrain over long distances, or to a higher elevation treatment plant. Force mains require robust pipes designed to withstand internal pressure and often incorporate pressure surge control devices to manage the forces generated by pumps.

How do regulations impact valve selection?

Municipal and state regulations often dictate minimum design criteria for sewer systems. These standards ensure that all components, including valves, meet specific performance and safety requirements for public infrastructure. For example, the North Carolina Department of Environment and Natural Resources covers minimum design criteria for gravity sewers, including slope gradient and velocity calculations. Similarly, in Mendocino City, California, specific design standards are outlined for sewer systems. These regulations guide engineers in selecting valves that comply with local codes, ensuring environmental protection, public health, and system longevity. Compliance often extends to material specifications, testing, and installation practices.

Conclusion

Gravity sewer systems, though often out of sight, are a cornerstone of modern public health and environmental management. Their effective operation relies on a complex interplay of engineering principles, from maintaining self-cleansing velocities to managing the dynamic forces within the pipelines. The selection of suitable gravity sewer valves is not merely a technical detail; it is a critical decision that directly impacts system reliability, infrastructure longevity, and the protection of community assets.

By understanding the fundamentals of gravity flow, recognizing the dangers posed by trapped air, vacuum, and pressure surges, and carefully choosing the right engineered valves for specific system conditions, we can ensure efficient wastewater management for generations to come. Investing in high-quality, purpose-built valves is an investment in resilient infrastructure and a healthier future.

Entrepreneur Resources Your source for small business information

Entrepreneur Resources Your source for small business information