When you’re new to the world of business, it can be tough to navigate. It’s no longer enough just to have a solid idea, a smart strategy, and a business degree. If you aspire to grow from plucky startup to global powerhouse, you’ll have to learn all about the trends in business. It’s not what you know; it’s who you know and what they tell you. There’s a reason networks and business conferences are as popular as ever. They present an opportunity for aspiring business brains to learn from industry leaders, peaks and troughs.

I’m working under the assumption that you’re already surrounding yourself with the right people. In that case, you’ve probably heard of a little something called ‘lean’ culture. It’s everywhere. From keynote speakers to Human Resources executives; they’re all espousing the principles of lean. How overhauling the way your business operates from top to bottom can, in turn, improve productivity, not to mention your profit margins.

That’s all well and good, of course, but what exactly does ‘lean’ entail? In a world that is filled with corporate buzzwords, what is just a passing phase and, equally, what is worth latching onto? Well, I am of the opinion that lean management is something that will ultimately prove to stand the test of time. Despite its recent upturn into the forefront of corporate thinking, lean is not a new phenomenon. Rather, its origins can be traced all the way back to Henry Ford, and, later, became synonymous with Toyota.

The methodical approach of lean is actually fairly simple to get your head around. In fact, it’s based on just five key principles, and they are as follows:

1 – Specify Value. From the perspective of your end customer, identify the value of your product or service. In layman’s terms, this means to ‘name your price’ of a service the customer would be willing to pay for. Accounting for both income and expenditure, step one is what ultimately what goes on to decide your profit margins.

2 – Streamline Value. This simply means to – with a fine toothed comb – go over every step in the process from the start point to the end point. Eliminate anything that doesn’t contribute directly to the aforementioned final value. By trimming the fat, you get leaner. Get it?

3 – Ease the Transition. It’s all about having the consumer – and endgame – as the focal point of your processes. Once you’ve eradicated the steps that do not ultimately increase value, it’s time to go one further. All the remaining steps should collaborate in harmony and without disruption. Your goal is to create a ‘stream’ that flows quickly and smoothly.

4 – Pull, Don’t Push. This is for those of the understanding that there are two types of business brain – the ‘push’ and the ‘pull.’ It’s all about logistics. Proponents of ‘push’ will base their decisions entirely on forecast. Creating more than you need, and trying to force the rest onto your consumer base. Lean management dictates – and advocates – the need for a ‘pull’ strategy. Think of it as creating on demand. Respond only to the direct demand of your customers.

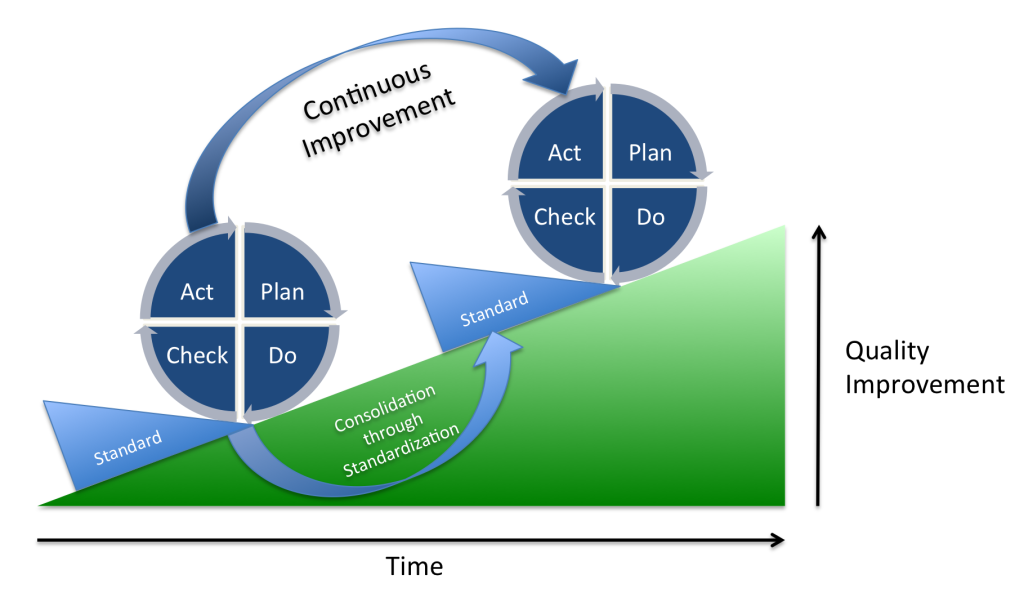

5 – Optimize Operation. With the four basic principles of lean culture in place, it’s now all about trial and error. It’s the theory that with every process that is undertaken, you’ll be able to learn from it and optimize the routine. It’s all about getting things down to a fine art, both to maximize productivity and profit margins.

It sounds pretty simple, right? But as it stands, they are just words on a page. How do you implement lean management into your business? Well, first of all, you have to have a firm belief that every aspect of an organization can be streamlined in such a way. From the manufacturing process, through to the sales department and customer care team. Every single process and member of staff within your existing structure should be with an eye on value.

The easiest way to achieve this is by incorporating these principles from the very beginning of your fledgling business. This is why it’s the ideal solution for start-ups in particular. There’s no need to change direction, or to go through a phase of transition. You impose these processes from the very start and maximize productivity from year zero. No rebuilding job required. Sounds good to me.

If you’d like some more expert advice about lean culture, you should consider enrolling for training. Courses such as the one at http://www.simplilearn.com/quality-management/lean-six-sigma-green-belt-training are well worth the investment. You can get advice from specialist instructors on how best to implement these principles into your business.

Continuous Improvement – Wikipedia

Continuous Improvement – Wikipedia

When enforcing these principles, you need to tabulate every aspect of your company into one of three categories.

- Value Contributors. The processes (or people) that, as mentioned above, directly contribute to the bottom line. Those Monday morning meetings that don’t seem to achieve anything? Yeah, we’re not fond of those, and they’re on the chopping block. Good news.

- Essential Exceptions. What doesn’t directly contribute to the end point, but is necessary regardless. For example, the time it takes to field a customer complaint. It’s not paying the bills (quite the opposite, in fact), but it’s entirely required.

- Value Inhibitors. You might call this ‘waste.’ These are entirely expendable, and, in truth, should be disposed of. As harsh as it sounds, that includes physical employees. But, if they aren’t demonstrating a purpose, why are they there in the first place?

Once you’ve gotten all of your company’s elements into one of these three categories, it becomes much easier to identify weak links. You can easily see exactly where your process is faltering and act swiftly and decisively upon it. You always have to have the endgame in the back of your mind. Everything within the structure of your business should be with an eye on creating value and maximizing productivity. Lean is more than just another corporate buzzword. It’s a stable, tried and tested way of thinking for creating a more sustainable culture.

Entrepreneur Resources Your source for small business information

Entrepreneur Resources Your source for small business information

Flickr.com

Flickr.com

Thanks for the sharing!

The most challenging part is to sustain the benefits and this is why a big number of projects fail.

Value proposition is quite great, been thinking of implementing lean management in my business from quite sometime now

thank you for sharing.